Smarte Technologien für langlebige Infrastruktur

Forschung trifft Fortschritt

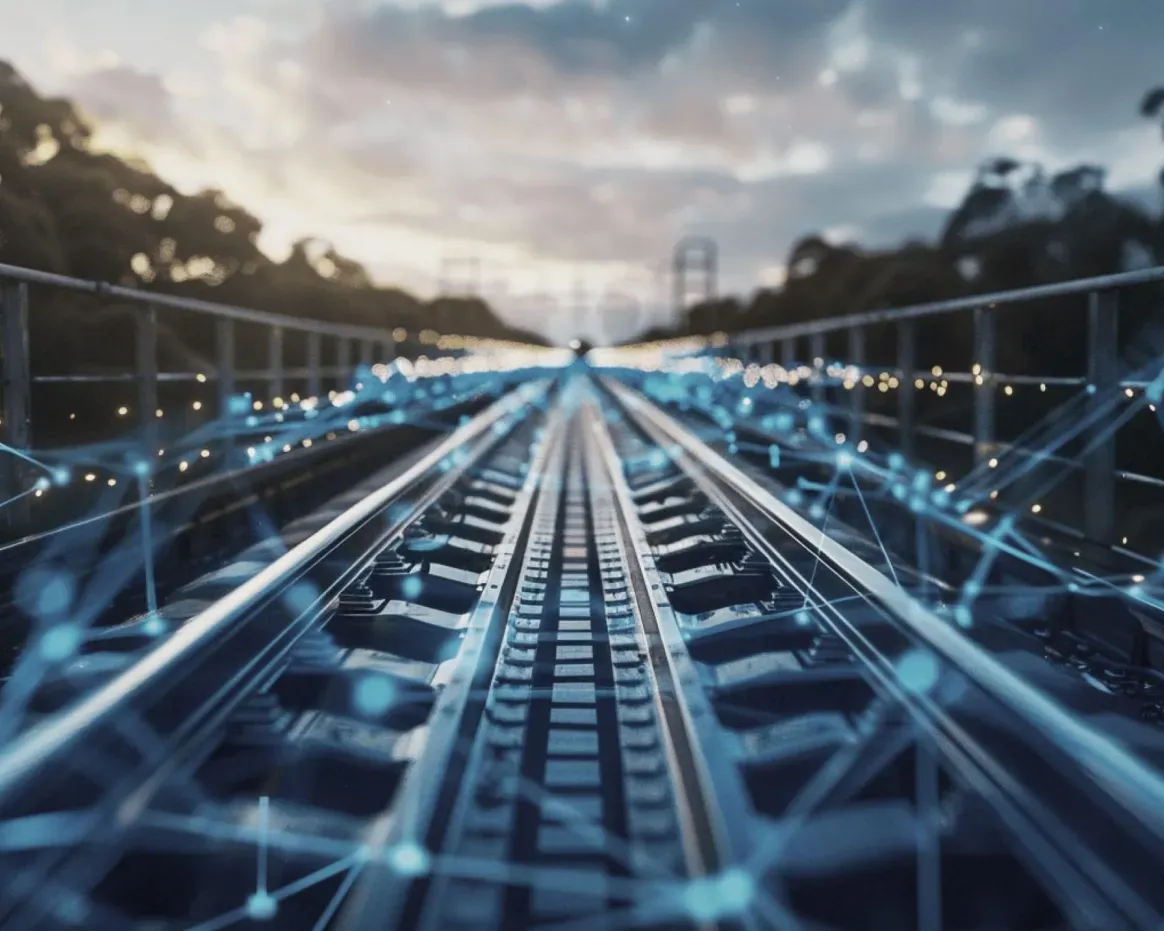

Rail Engineering verbindet modernste Technologie mit fundiertem Ingenieurwissen. Wir vermessen, bewerten und überwachen Bauwerke und Infrastrukturen digital - von Brücken über Gebäude bis hin zu Felswänden. Mit Sensorinstallationen, digitalen Zwillingen und vorausschauenden Analysen. Das Ergebnis: mehr Sicherheit, längere Lebensdauer und smarter Schutz für Ihre Infrastruktur.